Supplies & Electrodes

your needs. Our EDM consumables, including electrodes and electrode guides are fully customizable, and all supplies are made to your specifications. Supplies are stocked in anticipation of demand, ensuring that you aren’t left waiting for parts you need now.

- Custom EDM Guides and Electrodes: Tailored solutions to meet specific machining needs.

- Quality Assurance: ANSI inspection standards with NIST-certified precision tools.

- Dynamic Stocking System: Anticipates demand to minimize lead times.

- Expert Consultation: EDM specialists to optimize processes and results.

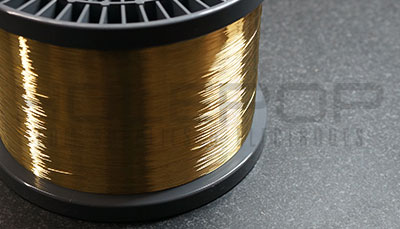

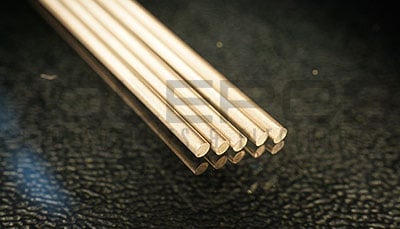

- Diverse Electrode Materials: Brass, copper, tungsten carbide, copper-tungsten, silver-tungsten, and molybdenum.

- Precision EDM Guides: Silicon nitride and ceramic guiding surfaces.

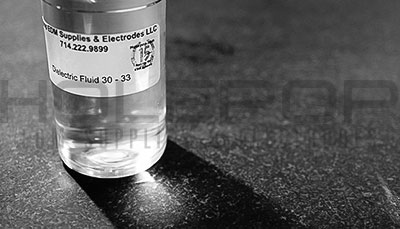

- Essential Components: Drill chucks and high-performance dielectric fluids.

- Flexible Ordering: Low MOQs and sample packs for testing.

- High-Volume Capability: Consistent quality for large-scale production.

- Electrode Variety: Wide range of sizes for all applications.

- Flow Testing: Verified electrode reliability and performance.

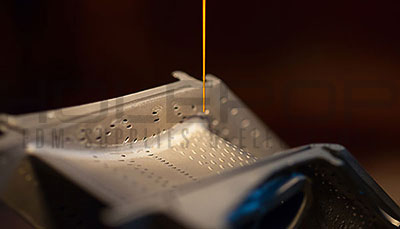

Holepop EDM Supplies & Electrodes is a leading EDM (Electrical Discharge Machining) supplier, delivering high-quality electrodes and guides for over 20 years. Trusted by industries like aerospace, biomedical technology, tool and die manufacturing, and defense, we enable the creation of cutting-edge products through precision and reliability.

Our extensive expertise, commitment to quality, and tailored EDM solutions ensure superior performance for mission-critical applications, helping companies achieve unmatched accuracy and efficiency.

The Holepop Difference

Why Companies Choose Holepop as Their EDM Supplier

At Holepop, we provide tailored solutions for EDM processes, taking the hassle out of parts procurement. Here’s why businesses choose us:

Value-Added Processes

- Custom Design Solutions: Our team works closely with engineers to provide EDM guides and electrodes tailored to your machining needs.

- Dynamic Stocking System: Minimize lead times with our proactive stocking system, ensuring your parts are ready when you need them.

- Uncompromising Quality: We use NIST-certified instruments with precision up to the fifth decimal place for rigorous quality control.

Comprehensive EDM Solutions

- Electrodes: High-performance brass, copper, copper-tungsten, and tungsten carbide materials.

- Guides: Choose from ceramic, ruby, or silicon nitride guiding surfaces for precision results.

- Drill Chucks & Dielectric Fluids: Essential components to optimize EDM machining performance.

- Customizable Solutions: Low minimum order quantities and tailored parts for unique requirements.

Partner with Holepop to experience precision, reliability, and seamless supply chain management for your EDM projects.