Achieve Precision with Tungsten Carbide Electrodes

Overview

Tungsten carbide EDM electrodes are the pinnacle of precision machining, offering unmatched hardness, wear resistance, and electrical conductivity. Designed for intricate geometries and tight tolerances, they are essential in high-precision industries such as aerospace, automotive, and medical manufacturing. Unlike traditional electrode materials, tungsten carbide withstands extreme thermal and mechanical stress, ensuring long-lasting performance with minimal deformation. This durability is critical in demanding EDM applications, where precision and consistency are essential for superior machining results. By maintaining structural integrity under high temperatures, these electrodes help manufacturers achieve tighter tolerances while reducing tool wear and production costs.

With their exceptional electrical conductivity, tungsten carbide electrodes facilitate high-speed EDM machining with greater stability, allowing for efficient material removal and extended tool life. Their reliability makes them a preferred choice for industries requiring the highest levels of accuracy and efficiency, ensuring optimized performance in even the most challenging machining environments.

Capabilities

Exceptional Wear Resistance

Tungsten carbide electrodes offer superior wear resistance, ensuring a significantly longer lifespan compared to traditional materials. Their durability minimizes electrode replacement frequency, maintaining consistent machining precision even under prolonged use.

High Thermal Stability

Engineered to withstand extreme thermal stress, these electrodes maintain their structural integrity and dimensional accuracy at high temperatures. This stability ensures reliable performance in demanding EDM applications, reducing deformation and machining errors.

Versatile Applications

Designed for precision EDM machining, tungsten carbide electrodes excel in sinker EDM, wire EDM, and micro-drilling. They offer superior performance in machining hardened metals, superalloys, and composites, making them indispensable for industries requiring high accuracy and efficiency.

Applications

Aerospace Components

Tungsten carbide electrodes enable the high-precision machining of turbine blades, heat shields, and structural components. Their wear resistance and thermal stability make them ideal for aerospace applications that demand tight tolerances and exceptional durability.

Automotive Parts

Essential for precision-engineered drivetrain and engine components, tungsten carbide electrodes enhance the production of high-performance and wear-resistant automotive parts. These electrodes help achieve superior surface finishes and extended tool life in machining hardened materials.

Medical Devices

Used in the fabrication of intricate surgical instruments, implants, and biocompatible components, tungsten carbide electrodes provide unmatched accuracy and repeatability. Their superior conductivity ensures the clean, precise cutting of delicate materials used in medical applications.

Mold Making

Ideal for creating complex, high-precision molds and dies, tungsten carbide electrodes ensure the production of durable and detailed cavity molds. Their hardness and stability reduce tool wear, improving efficiency in injection molding, die casting, and stamping applications.

Silicon Wafer Production with Tungsten Carbide

Tungsten carbide EDM electrodes play a critical role in silicon wafer manufacturing, enabling precise slicing, drilling, and etching essential for semiconductor fabrication. Their exceptional durability and precision make them an ideal choice for achieving uniform wafer thickness and high-resolution micro-drilling in advanced electronics and photovoltaic applications.

With superior wear resistance, these electrodes ensure consistent performance in high-production environments, reducing tool degradation and improving processing efficiency. They also maintain thermal stability under extreme conditions, allowing for precise micro-machining without distortion.

Tungsten carbide EDM electrodes support the fabrication of next-generation electronic components, including photovoltaic cells, microprocessors, and semiconductor circuits, making them indispensable in high-tech manufacturing.

Learn more about our Silicon Wafer Production capabilities.

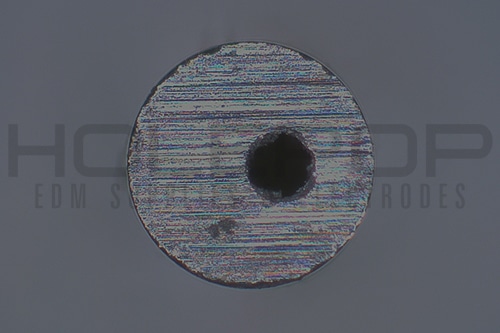

Tungsten Carbide Single Hole Tubes

Tungsten carbide single-hole tubes offer unmatched durability and precision in EDM drilling, making them the preferred choice for machining exotic metals and superalloys such as cobalt and nickel. Engineered for through-hole applications, these electrodes ensure smooth, accurate, and efficient drilling through even the toughest materials. Their exceptional wear resistance and thermal stability allow for consistent performance in high-precision machining environments.

Tungsten Carbide Solid Rods

Tungsten carbide rods provide the lowest wear rate among EDM drilling materials, making them the ideal choice for blind hole drilling applications. Renowned for their exceptional durability and precision, these rods excel in machining hardened steels, superalloys, and advanced composites. Their superior wear resistance and thermal stability ensure consistent performance, even in the most demanding EDM operations.

Tungsten Carbide Offset Inner-Channel Tubes

Offset inner-channel tubes feature a helix drilling pattern, ensuring clean, debris-free holes. These innovative tungsten carbide electrodes reduce wear, extend electrode life, and streamline production for advanced industries like aerospace and medical devices.

Tungsten Carbide Dual Channel Tubes

Dual-channel tubes deliver unmatched precision and superior cooling efficiency, making them essential for machining superalloys, hardened steels, and high-performance materials. Their advanced dual-channel design enhances electrode flushing, reduces heat buildup, and ensures consistent accuracy in demanding EDM operations. By improving thermal management, these tubes help minimize downtime, extend tool life, and optimize machining performance.

Contact Us

Optimize your EDM processes with tungsten carbide electrodes. Contact Holepop today to learn how we can elevate your manufacturing capabilities.