Unlock Precision with Brass EDM Electrodes

Overview

Brass EDM electrodes are renowned for their precision, efficiency, and versatility in high-performance machining applications. With excellent electrical conductivity and cost-effectiveness, these electrodes enable fast material removal while maintaining exceptional surface finishes, making them a preferred choice for a wide range of industries.

Ideal for aerospace, automotive, and electronics manufacturing, brass electrodes play a crucial role in EDM drilling, micro-machining, and intricate component fabrication. Their unique composition enhances process stability, ensuring consistent results in high-precision EDM applications.

Capabilities

High Precision and Cutting Efficiency

Brass EDM electrodes offer exceptional electrical conductivity and a low melting point, enabling faster material removal and precise machining of complex geometries. This enhances productivity while maintaining superior accuracy in EDM applications.

Versatility for Multiple Applications

Designed for compatibility with steel, aluminum, titanium, and other conductive materials, brass electrodes are widely used in aerospace, automotive, and electronics manufacturing. Their adaptability makes them ideal for micro-machining, die sinking, and intricate component fabrication.

Superior Surface Finish and Cost Efficiency

Brass electrodes deliver smooth surface finishes, minimizing the need for secondary post-processing. This reduces overall machining costs while ensuring consistent, high-quality results in precision manufacturing.

Applications

Aerospace Components

Brass EDM electrodes provide high-precision machining for turbine blades, heat-resistant alloys, and structural aerospace components, ensuring reliability in extreme environments.

Automotive Parts

Used in the production of intricate, high-durability automotive components, including engine parts, fuel injection systems, and performance-enhancing mechanisms.

Electronics Manufacturing

Ideal for micro-machining and intricate component fabrication, brass electrodes enable the precise production of circuit boards, connectors, and fine electrical components.

Medical Devices

Brass electrodes support high-precision machining of surgical instruments, implants, and micro-medical components, meeting stringent industry standards.

Brass EDM Electrodes in Silicon Wafer Production

Brass EDM electrodes play a crucial role in silicon wafer manufacturing, offering exceptional precision for micro-drilling and intricate machining. Their high electrical conductivity ensures consistent, high-quality wafer production, meeting the stringent demands of the semiconductor and electronics industries.

- High-precision drilling for complex wafer patterns, ensuring micron-level accuracy.

- Reduced electrode wear for cost-effective, long-lasting machining performance.

- Superior surface finishes to enhance wafer efficiency and conductivity.

Discover how our Silicon Wafer Production solutions leverage brass EDM electrodes for advanced semiconductor applications.

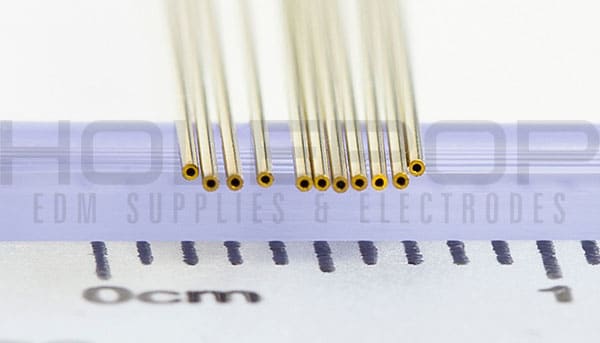

Single Hole Brass EDM Electrodes

Single-hole brass electrodes provide high-precision machining and efficient debris removal, making them indispensable for intricate EDM applications. Their superior conductivity and wear resistance ensure consistent performance in industries such as aerospace, automotive, and electronics manufacturing.

Multi-Channel Brass EDM Electrodes

Multi-channel brass electrodes optimize debris flushing and thermal regulation, enabling faster machining speeds and extended electrode life. Their advanced design enhances cooling efficiency, reducing wear and improving performance in high-precision EDM applications.

EDM Brass Rods

EDM brass rods provide superior electrical conductivity and high-precision machining capabilities, making them ideal for drilling, cutting, and shaping intricate components. Their durability and efficiency make them essential in industries such as aerospace, automotive, and electronics manufacturing.

Customization

Custom brass electrodes are available in various sizes, lengths, and configurations to meet your machining requirements. We offer both single-hole and multi-channel options tailored to your specific needs.

Contact Us

Discover the capabilities of brass EDM electrodes for your machining projects. Contact Holepop today to learn more or to request custom solutions.