Pure Tungsten-Wolfram EDM Electrodes

Pure Tungsten-Wolfram EDM Electrodes at Holepop

What Are Pure Tungsten-Wolfram EDM Electrodes?

- Extreme Durability: Handles heavy-duty applications without deformation.

- Thermal Stability: Ensures consistent performance during intense EDM operations.

- Precision: Maintains intricate details in exotic metals and superalloys.

Why Use Pure Tungsten-Wolfram EDM Electrodes?

Superior Durability and Precision

Pure Tungsten-Wolfram EDM electrodes are built to last, offering extended lifespans while maintaining high-precision results. Their wear resistance ensures smooth operation with minimal degradation, even during demanding tasks.

Exceptional Conductivity

With high thermal and electrical conductivity, these electrodes achieve precise, clean cuts and excellent surface finishes. Their efficient energy use minimizes downtime caused by frequent replacements.

Versatility Across Industries

From small hole drilling to wire and sinker EDM, these electrodes excel in diverse machining processes. Industries such as aerospace, automotive, and mold-making rely on tungsten electrodes for their unmatched accuracy and quality.

Key Benefits

- Unmatched stability: Secure workpiece holding for precise machining.

- Enhanced longevity: Reduced wear for extended usage.

- Improved cost efficiency: Less frequent replacements mean long-term savings.

Pure Tungsten-Wolfram EDM Solid Rods

Pure Tungsten-Wolfram EDM solid rods are precision-engineered tools designed for electrical discharge machining (EDM) applications. These rods are made from pure tungsten, also known as wolfram, which is renowned for its high melting point, extreme hardness, and exceptional wear resistance. These properties make Pure Tungsten-Wolfram EDM solid rods ideal for machining complex shapes and intricate details in hard metals.

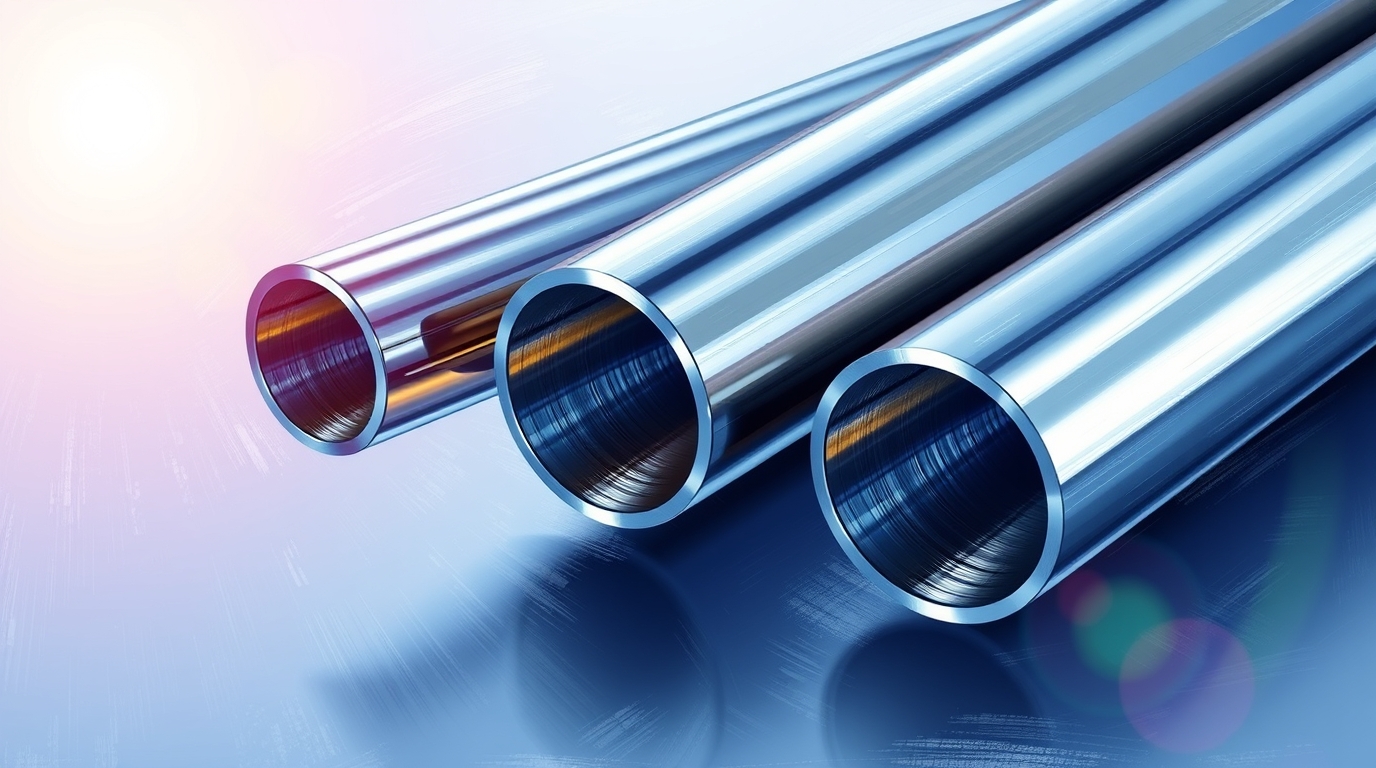

Pure Tungsten-Wolfram EDM Tubes

Pure tungsten-wolfram EDM tubes are engineered for maximum heat resistance and unmatched durability. These tubes excel in high-temperature environments and offer superior performance for precision machining tasks in aerospace, medical, and electronics industries.

Pure Tungsten-Wolfram EDM Wire

Pure Tungsten-Wolfram EDM wire is a high-performance tool designed for precision electrical discharge machining applications. This wire is made from pure tungsten, also known as wolfram, which is prized for its exceptional hardness, high melting point, and superior wear resistance. These properties make Pure Tungsten-Wolfram EDM wire ideal for achieving precise cuts and intricate details in hard metals.

Why Choose Holepop Pure Tungsten-Wolfram EDM Electrodes?

Choosing the right EDM electrode is crucial for optimizing your machining processes. Our Pure Tungsten-Wolfram EDM electrodes are engineered to deliver superior performance, ensuring that your EDM operations are efficient, precise, and reliable. With a wide range of products tailored to various EDM applications, Holepop offers solutions that meet the specific needs of modern machining.

Explore our range of Pure Tungsten-Wolfram EDM electrodes at Holepop and find the perfect solution for your EDM needs. Contact our expert team for further assistance and technical support.

By selecting Holepop Pure Tungsten-Wolfram EDM electrodes, you can ensure optimal performance, enhanced efficiency, and superior quality in your EDM operations.