EDM Consumables

What are EDM Consumables?

The term EDM consumables is a slightly more specific term for EDM supplies—EDM consumables are simply EDM supplies that are consumed. Though this distinction may seem obvious and pedantic, the subtle differences between something that is consumed and something that is permanent lead to significantly different considerations when purchasing supplies.

So What Are These Differences Exactly?

- Consumables have a relatively short life span.

- Consumables are purchased in large quantities.

- The quality of individual consumables cannot be measured as efficiently.

- Consumables cannot be cost-effectively repaired like a machine.

-

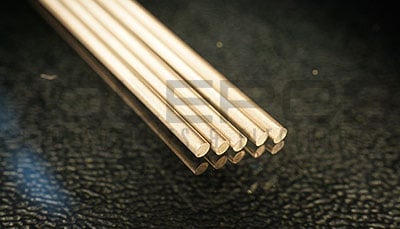

Electrodes

Electrodes are the consumable that electrical discharge machining revolves around. The machines, guides, dielectric fluid, and chucks are all just accessories to making sure that the electrode drills the way it’s supposed to. Electrodes are available in brass, copper, tungsten carbide, copper-tungsten, silver-tungsten, and molybdenum. See our electrodes page for more information.

-

Brass Wire

Spools of wire are used in the majority of EDM applications, in which workpieces are sliced like cheese with cheese wire. This type of machining is called wire EDM. We now stock brass wire, and zinc-coated brass wire. Brass wire is a cost-effective solution for most wire EDM applications, while zinc-coated wire is suited to more demanding applications where fine surface finish, higher speed, or higher productivity are required.

-

Guides

Guides put electrodes where they’re supposed to be. Guides are available with silicon nitride and conventional ceramic guiding surfaces. Silicon nitride guides last much longer, have greater guiding surface area and electrode contact with less friction, and are fully customizable. Ceramic guides are readily available in a wide range of standard sizes. Ceramic guides are customizable, but with less freedom than silicon nitride. See our guides page for more information.

-

Chucks

A chuck connects an electrode to an EDM machine. A good chuck needs to grip tightly, withstand the erosive forces of electrical sparking, and hold an electrode straight, with no wobble. Keyed and keyless chucks are available from Yukiwa and Albrecht. Both manufacturers offer high quality, reliable chucks. Albrecht chucks are higher quality, but less economical than Yukiwa chucks. See our ER Collet Chuck, keyed, and keyless chuck pages for more information.

-

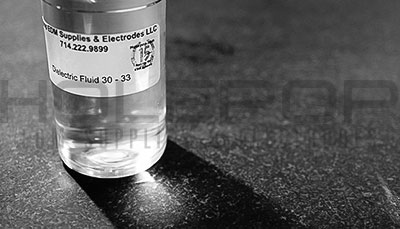

Dielectric Fluid

Electrodes are the consumable that electrical discharge machining revolves around. The machines, guides, dielectric fluid, and chucks are all just accessories to making sure that the electrode drills the way it’s supposed to. Electrodes are available in brass, copper, tungsten carbide, copper-tungsten, silver-tungsten, and molybdenum. See our electrodes page for more information.

-

Resources

For more information on electrodes, guides, accessories, or dielectric fluid, please see our resources page. There you will find our brochure, along with specification sheets for electrodes, guides, accessories, and dielectric fluid. If you still have questions that are not answered by our resources, do not hesitate to call us at +1 (714) 222-9899, or email us at info@holepop.com.

What Are the Consequences of These Differences?

As the lifespan of a consumable is generally known or predictable, and cannot be extended with repair like a complex machine, the quality or material of a consumable can become a deciding factor in purchasing. Though an electrode may cost twice as much as another, if it lasts three times as long, it becomes much cheaper over time. For an electrode, material determines lifespan, as material determines the wear-rate. Unlike other consumables, this is rarely a factor in electrode selection, however, as materials are sought after for their ability to drill through certain targets, not for their durability. This means that the increase in prices of electrodes with the lowest wear-rate are often not proportional to the increase in lifespan. For instance, it would not be recommended to use tungsten carbide electrodes in place of brass when brass could be used at all—one would pay on the order of ten times the price of a brass electrode for an equivalent tungsten carbide electrode, for a doubling of lifespan.

For guides, material selection has a much larger impact on lifespan, an impact that outstrips the difference in price. Silicon nitride, an advanced ceramic compound used in our customized guides, increases a guide’s lifespan by five to ten times. For machine shops that manufacture parts predictably and for long production runs, a longer lasting guide makes perfect sense. The only situation in which the price of silicon nitride becomes a liability is where its superior lifespan cannot be taken advantage of. This can be a problem in prototyping shops, where contracts are unpredictable one-offs. It is better to have a large number of cheap guides in a wide range of sizes, rather than a few expensive guides that won’t be used very much.

Quality is a factor in the purchasing of chucks and dielectric fluid. For chucks, general manufacturing quality is more of a factor than the material itself. This is because as the teeth of a chuck degrade, the loss of definition in the shape of the teeth accelerates with wear. This means that even a relatively small difference in initial sharpness between chucks can slow down wear significantly, and explains the relative value of Albrecht chucks in comparison to Yukiwa. Though both Albrecht and Yukiwa chucks are fine chucks when new, the slightly greater precision of Albrecht chucks results in a much longer lasting product. So while Albrecht may seem unnecessarily expensive when compared to Yukiwa, this difference in price is well justified. For dielectric fluid, synthetic fluids are of generally higher quality than petroleum-based fluids. Petroleum-based and synthetic fluids can be blended, and the quality of a fluid rises as the proportion of synthetic fluid to petroleum-based fluid grows.

As much of a factor as quality is in the performance of consumables, the capability to effectively check the quality of any consumable is inversely proportional to the amount of consumable required. This can become a significant issue with brass and copper electrodes, which are commonly ordered in the thousands. Checking so many electrodes individually would be very time consuming, and not warranted given the low individual piece price. Fortunately, quality assurance of a random sample of electrodes from an order is statistically almost as effective in assessing the quality of a lot as checking individual electrodes. And though individual electrodes cannot be discarded using this method, the probability of any one electrode being unusable can be assessed with confidence.