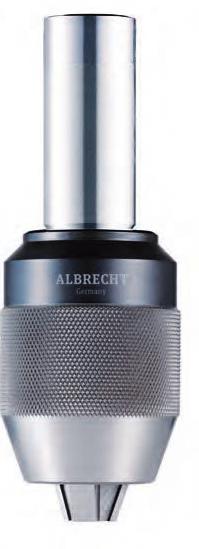

Albrecht Precision Chucks

What Are Albrecht Precision Chucks?

Albrecht Precision Chucks are high-performance clamping devices engineered for precision machining. With innovations like the patented self-tightening mechanism and unparalleled run-out accuracy, these chucks set the standard in machining operations worldwide. Perfect for a variety of applications, from precision drilling to high-speed operations, Albrecht chucks are built for reliability and durability.

Sensitive-Drill-Feed Specifications

Albrecht’s Sensitive-Drill-Feed is designed for delicate operations, featuring a precisely ground shank, guide ring with ball bearings, and a spring return mechanism. It offers unmatched control and precision in machining applications.

| Form | Option | Part Number | L1 | L2 | D | Balanced | Weight (kg) |

|---|---|---|---|---|---|---|---|

| MK1 | DIN 228 | 200 MK01 000 0 | 82 | 96 | 20 | 20,000 | 0.10 |

| Ø13 | Cylindrical Shank | 200 Z130 000 0 | 66 | 80 | 13 | 20,000 | 0.10 |

Self-Tightening Drill Chucks (0.2 – 1.5 mm)

Designed for high-precision machining, these self-tightening drill chucks provide a secure grip and are perfectly balanced for demanding operations. Available in multiple configurations for various applications.

| Form | Option | Part Number | L1 | L2 | D | Balanced | Weight (kg) |

|---|---|---|---|---|---|---|---|

| B06 | ISO 239 | 100 0015 B06 0 | 35 | 37 | 19 | 20,000 | 0.05 |

| B06 | 1.8 mm Through Hole | 100 0015 B06 A | 35 | 37 | 19 | 20,000 | 0.05 |

| J0 | ISO 239 | 100 0015 J00 0 | 35 | 37 | 19 | 20,000 | 0.05 |

| J0 | 1.8 mm Through Hole | 100 0015 J00 A | 35 | 37 | 19 | 20,000 | 0.05 |

Self-Tightening Drill Chucks (0.2 – 3.0 mm)

Perfect for clockwise operations, these self-tightening drill chucks are designed for precision machining applications that demand minimal run-out and exceptional durability.

| Form | Option | Part Number | L1 | L2 | D | Balanced | Weight (kg) |

|---|---|---|---|---|---|---|---|

| B06 | ISO 239 | 100 0030 B06 0 | 44 | 48 | 24 | 20,000 | 0.10 |

| B06 | 3.0 mm Through Hole | 100 0030 B06 A | 44 | 48 | 24 | 20,000 | 0.10 |

| B10 | ISO 239 | 100 0030 B10 0 | 44 | 48 | 24 | 20,000 | 0.10 |

| B10 | 3.0 mm Through Hole | 100 0030 B10 A | 44 | 48 | 24 | 20,000 | 0.10 |

| J0 | ISO 239 | 100 0030 J00 0 | 44 | 48 | 24 | 20,000 | 0.10 |

Self-Tightening Drill Chucks (0.5 – 6.5 mm)

Ideal for heavy-duty machining operations, these self-tightening drill chucks are robustly designed to provide exceptional grip strength and stability, ensuring high precision in challenging environments.

| Form | Option | Part Number | L1 | L2 | D | Balanced | Weight (kg) |

|---|---|---|---|---|---|---|---|

| B10 | ISO 239 | 100 0065 B10 0 | 62 | 68 | 34 | 20,000 | 0.30 |

| B12 | ISO 239 | 100 0065 B12 0 | 62 | 68 | 34 | 20,000 | 0.30 |

| J1 | ISO 239 | 100 0065 J01 0 | 62 | 68 | 34 | 20,000 | 0.30 |

Self-Tightening Drill Chuck for Highest Quality

With inner taper or thread, these self-tightening drill chucks are built for exceptional quality and precision. Available in multiple capacity ranges and configurations to suit diverse machining needs.

0.5 – 10 mm

| Form | Option | Part No. | L1 | L2 | D | Balanced | Weight (kg) |

|---|---|---|---|---|---|---|---|

| B12 | ISO 239 | 100 0100 B12 0 | 80 | 92 | 43 | 0.60 | |

| B16 | ISO 239 | 100 0100 B16 0 | 80 | 92 | 43 | 0.60 | |

| 5/8″-16 UNF | 100 0100 G04 0 | 80 | 92 | 43 | 0.60 | ||

| J02 | ISO 239 | 100 0100 J02 0 | 80 | 92 | 43 | 0.60 | |

| J33 | ISO 239 | 100 0100 J33 0 | 80 | 92 | 43 | 0.60 |

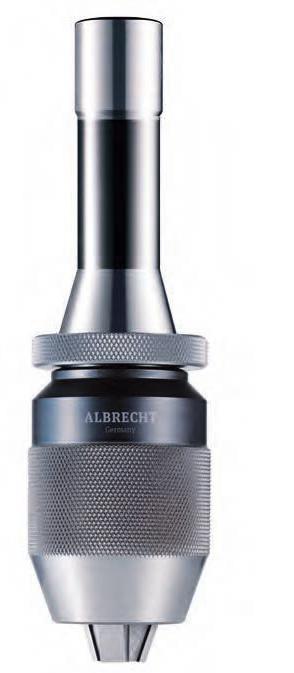

Self-Tightening Drill Chuck with Integrated Cylindrical Shank

Ideal for your turning machines, these self-tightening drill chucks with integrated cylindrical shanks offer precision and durability for machining applications.

1 – 13 mm

| Form | Part No. | L1 | L2 | D | Balanced | Weight (kg) |

|---|---|---|---|---|---|---|

| Ø16 × 60 Cylindrical Shank | 100 0130 Z16 0 | 79 | 91 | 50 | 1.00 | |

| Ø32 × 60 Cylindrical Shank | 100 0130 Z32 0 | 70 | 82 | 50 | 1.20 | |

| Ø5/8″ × 60 Cylindrical Shank | 100 0130 Z58 0 | 79 | 91 | 50 | 1.00 |

Self-Tightening Drill Chuck with Integrated R8 Shank

Ideal for your Bridgeport machine, these self-tightening drill chucks with integrated R8 shanks are designed for high performance and precision.

1 – 13 mm

| Form | Part No. | L1 | L2 | D | Balanced | Weight (kg) |

|---|---|---|---|---|---|---|

| R8 Bridgeport | 100 0130 R08 0 | 84 | 96 | 50 | 7,000 | 1.25 |

3 – 16 mm

| Form | Part No. | L1 | L2 | D | Balanced | Weight (kg) |

|---|---|---|---|---|---|---|

| R8 Bridgeport | 100 0160 R08 0 | 87 | 101 | 56 | 4,500 | 1.55 |

Self-Tightening Drill Chucks for Semi-Automatic Machines

Designed for semi-automatic machines, these self-tightening drill chucks provide quick tool changes with an integrated taper shank and key for additional clamping force. Ideal for high-efficiency operations.

1 – 13 mm

| Form | Option | Part No. | L1 | L2 | D | Balanced | Weight (kg) |

|---|---|---|---|---|---|---|---|

| A40 | DIN 69871 ISO 7388-1 | 100 4130 240 0 | 86 | 98 | 50 | 1,700 | 1.70 |

3 – 16 mm

| Form | Option | Part No. | L1 | L2 | D | Balanced | Weight (kg) |

|---|---|---|---|---|---|---|---|

| A40 | DIN 69871 ISO 7388-1 | 100 4160 240 0 | 89 | 103 | 56 | 1,900 | 1.90 |

Cylindrical Shanks

These cylindrical shanks are precision-engineered for various machining applications, offering reliable performance and durability. Available in multiple sizes and configurations to suit your specific requirements.

| Form | Part No. | L1 | D | Weight (kg) |

|---|---|---|---|---|

| B6 | 220 0635 B06 0 | 35 | 6 | 0.01 |

| B6 | 220 0660 B06 0 | 60 | 6 | 0.02 |

| B10 | 220 0835 B10 0 | 35 | 8 | 0.03 |

| B10 | 220 1050 B10 0 | 50 | 10 | 0.04 |

| B12 | 220 1050 B12 0 | 50 | 10 | 0.05 |

| B16 | 220 1260 B16 0 | 60 | 12 | 0.09 |

| B16 | 220 1650 B16 0 | 50 | 16 | 0.12 |

| B16 | 220 2060 B16 0 | 60 | 20 | 0.20 |

| J0 | 226 3821 J00 0 | 2 1/2″ | 3/8″ | 0.04 |

| J0 | 226 1221 J00 0 | 2 1/2″ | 1/2″ | 0.07 |

| J1 | 226 3821 J01 0 | 2 1/2″ | 3/8″ | 0.05 |

| J1 | 226 1221 J01 0 | 2 1/2″ | 1/2″ | 0.07 |

| J1 | 226 5821 J01 0 | 2 1/2″ | 5/8″ | 0.11 |

| J2 | 226 1221 J02 0 | 2 1/2″ | 1/2″ | 0.09 |

| J2 | 226 3403 J02 0 | 3″ | 3/4″ | 0.20 |

| J33 | 226 1221 J33 0 | 2 1/2″ | 1/2″ | 0.10 |

| J33 | 226 5821 J33 0 | 2 1/2″ | 5/8″ | 0.14 |

| J33 | 226 0103 J33 0 | 3″ | 1″ | 0.35 |

| J6 | 226 1221 J06 0 | 2 1/2″ | 1/2″ | 0.11 |

| J6 | 226 3403 J06 0 | 3″ | 3/4″ | 0.22 |

| J6 | 226 5821 J06 0 | 2 1/2″ | 5/8″ | 0.14 |

Why Choose Albrecht Drill Chucks?

Albrecht Drill Chucks have been the gold standard in precision machining for over 90 years. With a comprehensive range of products tailored to every machining requirement, Albrecht ensures exceptional performance, reliability, and durability. Whether you need high-precision keyless chucks, heavy-duty solutions, or corrosion-resistant designs, Albrecht provides unparalleled quality to meet your needs.

- Precision: Unmatched accuracy for demanding machining tasks.

- Durability: Built to withstand harsh environments and heavy-duty use.

- Versatility: A wide range of options for various applications.

- Efficiency: Quick-change and keyless mechanisms for reduced downtime.

- Specialization: Custom designs for specific industries like aerospace, medical, and automotive.

Invest in Albrecht Drill Chucks to elevate your machining processes. Backed by decades of innovation, Albrecht products deliver consistent results, making them the trusted choice for professionals worldwide.