Unlock Precision with Brass EDM Electrodes

Overview

Brass EDM electrodes are highly valued for their precision, efficiency, and adaptability across various industries. Known for their excellent electrical conductivity and affordability, brass electrodes excel in delivering superior surface finishes and fast machining speeds. Whether used for aerospace components, automotive parts, or electronics manufacturing, brass electrodes are an indispensable tool in electrical discharge machining (EDM) processes.

Capabilities

Exceptional Precision and Efficiency

With excellent electrical conductivity and low melting points, brass electrodes achieve intricate machining with high precision and faster cutting speeds, enhancing overall productivity.

Versatility Across Applications

Brass electrodes can handle a wide range of materials, including steel, aluminum, and titanium. This versatility makes them ideal for industries such as aerospace, automotive, and electronics.

Superior Surface Finish

Brass electrodes are known for producing smooth surface finishes, reducing the need for post-machining processes and ensuring cost-effective operations.

Applications

Aerospace Components

Brass electrodes deliver high precision for machining turbine blades and other heat-resistant aerospace components.

Automotive Parts

Used for producing intricate and durable parts for high-performance vehicles.

Electronics Manufacturing

Ideal for detailed work required in the production of electronic components and micro-scale parts.

Medical Devices

Brass electrodes are used in machining parts for high-precision medical instruments.

Brass EDM Electrodes in Silicon Wafer Production

Brass EDM electrodes are instrumental in silicon wafer production, particularly in micro-drilling and intricate machining processes. Their excellent electrical conductivity and precision make them ideal for creating consistent and high-quality wafers, meeting the rigorous standards of the semiconductor and electronics industries.

- High-precision drilling for intricate wafer patterns

- Reduced electrode wear for cost-efficient production

- Superior surface finishes for optimal wafer performance

Learn more about our Silicon Wafer Production solutions and how brass EDM electrodes play a pivotal role in advanced semiconductor manufacturing.

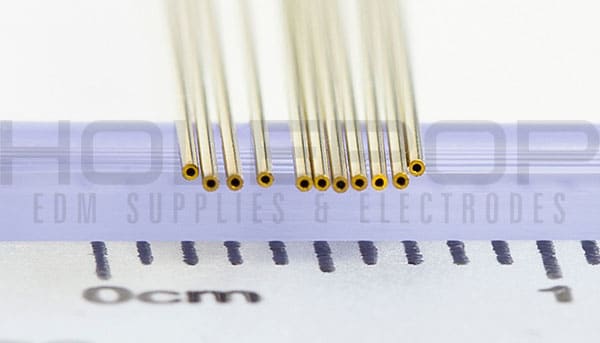

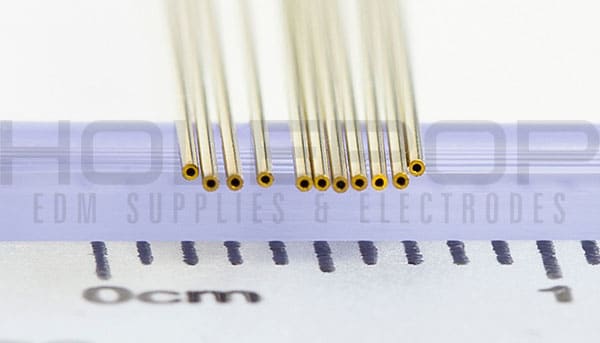

Single Hole Brass EDM Electrodes

Single-hole brass electrodes offer precise machining and efficient debris removal, making them essential for detailed EDM work across aerospace, automotive, and electronics industries.

Multi-Channel Brass EDM Electrodes

Multi-channel brass electrodes enhance debris flushing and cooling, ensuring faster machining speeds and reduced wear for high-precision applications.

EDM Brass Rods

EDM brass rods offer exceptional conductivity and precision, making them ideal for drilling, cutting, and shaping intricate components across diverse industries.

Customization

Custom brass electrodes are available in various sizes, lengths, and configurations to meet your machining requirements. We offer both single-hole and multi-channel options tailored to your specific needs.

Contact Us

Discover the capabilities of brass EDM electrodes for your machining projects. Contact Holepop today to learn more or to request custom solutions.